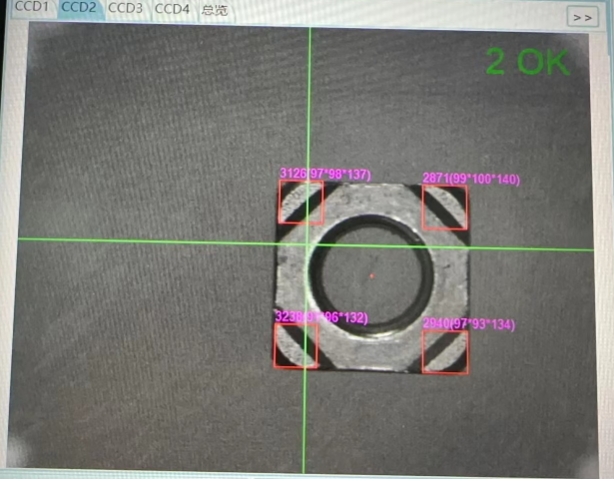

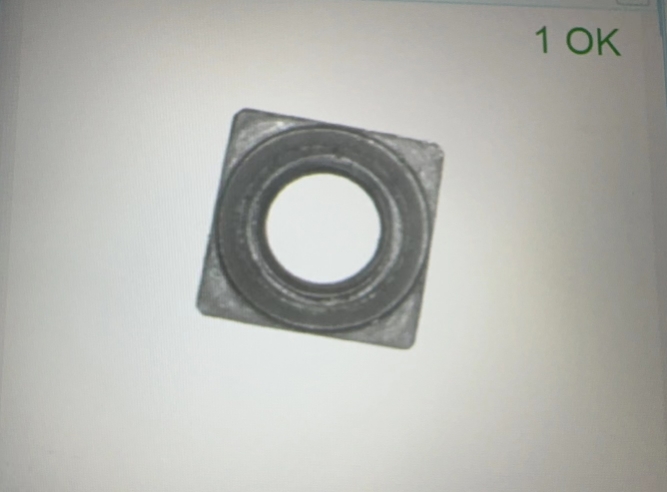

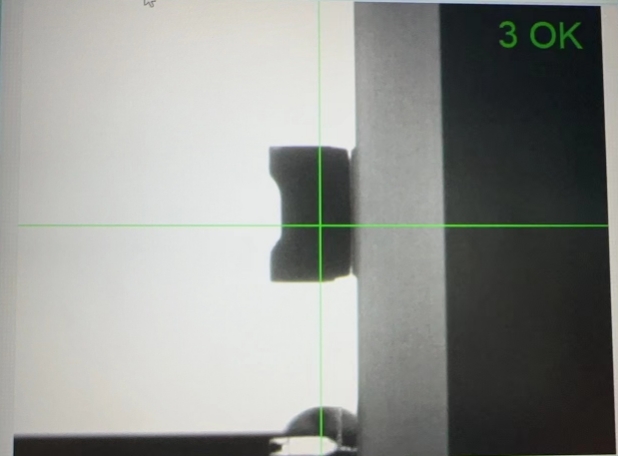

Optical inspection equipment (pipeline online inspection equipment) takes real-time nut images on the assembly line through industrial cameras or sensors to obtain high-definition and clear image data. The acquired images are preprocessed, including denoising, contrast enhancement, edge detection, etc., to improve the quality and clarity of the images and facilitate the subsequent feature extraction and defect recognition. The key features of nut, such as shape, size, position, color and texture, are extracted from the image by image processing algorithm. The extracted feature information is compared with the preset standard template or qualified product features in the database to judge whether the nut has defects or does not meet the requirements.

According to the results of comparative analysis, output test conclusions, such as qualified products, unqualified products, etc., and real-time feedback through sound and light alarm, rejection device, etc., in order to timely deal with unqualified products.