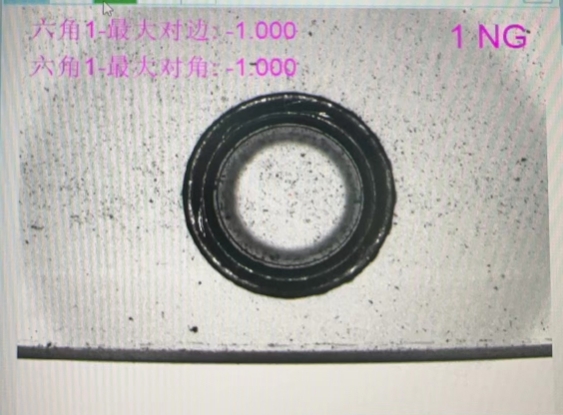

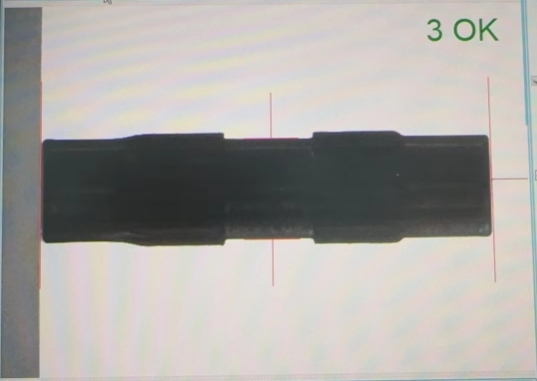

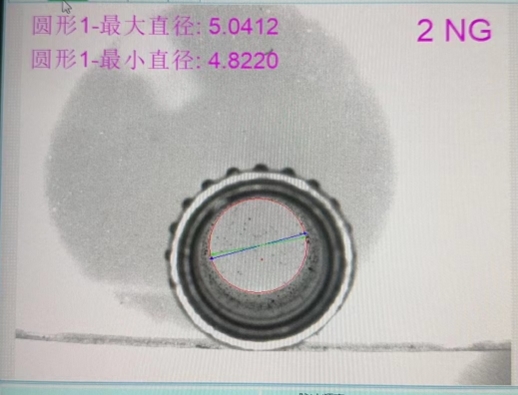

Compared with traditional detection methods, the on-line detection equipment has achieved a qualitative leap in detection speed and accuracy. Its high-speed image acquisition and processing system can process hundreds of product images per second, combined with advanced AI algorithms to achieve instant judgment and feedback on defects, greatly shortening the detection cycle and improving production efficiency. At the same time, through the integrated data analysis module, the equipment can continuously learn to optimize the detection model, adapt to the subtle changes of different batches of products, and maintain the stability of the detection accuracy.

The successful application of the online testing equipment not only solves the long-term quality inspection problems in the riveting pipe industry, but also provides a referential solution for the quality inspection of related products in many fields such as automobile manufacturing, aerospace, and new energy. By improving the intelligent level of quality inspection, enterprises can effectively reduce the rate of defective products, reduce material waste and production costs, and enhance market competitiveness.